- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Angle Steel Tower

- Electric Transmission Angle Steel Tower

- Communication Angle Steel Tower

- Monitoring Angle Steel Tower

- 220kv Transmission Line Electric Angle Steel Tower

- 110kv Transmission Line Electric Angle Steel Tower

- 330kv Transmission Line Electric Angle Steel Tower

- 500kv Transmisson Line Angle Steel Tower

- 66kv Angle Steel Tower

- 66KV Angle Steel Electric Power Tower

- Communication Towr

- Steel Pipe Tower

- Transmission Line Steel Pipe Tower

- Single Steel Pipe Tower

- Telecommunication Steel Pipe Tower

- Monopole Steel Pipe Tower

- 3 Leg Steel Tube Pipe Tower

- 220KV Steel Pipe Tower

- 110KV Steel Pipe Tower

- Lightning Steel Pipe Tower

- 500KV Steel Pipe Tower

- 66KV Steel Pipe Tower

- 330 KV Steel Pipe Tower

- Telecommunication Single Tubular Tower

- 10KV Steel Pipe Tower

- 10KV SIngle Pipe Tower

- 800KV Steel Pipe Tower

- Single Pipe Tower

- 132KV Steel Pipe Electric Power Tower

- 10KV-220KV Steel Pipe Electric Power Tower

- 4 Leg Telecommunication Microwave Tower

- High Voltage Communication Tower

- High Voltage Tesnsion Power Tower

- Single Tubular Monopole Tower

- Substation Steel Structure

- Angle Bar Tower

- 750KV Angle Steel Transmission Line Tower

- 10KV 33KV Transmission Line Tower

- 330KV Angle Steel Transmission Line Tower

- Tesioning Electric Transmission Tower

- 1000KV Electric Angle Steel Tower

- Lightning Tower

- Training Tower

- WiFi Communication Tower

- Power Line Tower

- Tangent Suspension Tower

- Terminal Tower

- Tension Steel Tower

- Single Monopole Tower

- Suspension Angle Steel Line Tower

- Angular Steel Electric Tower

- High Voltage Tower

- 66kv 120kv 220kv Steel Tower

- Transmission Electric Line Steel Lattice Tower

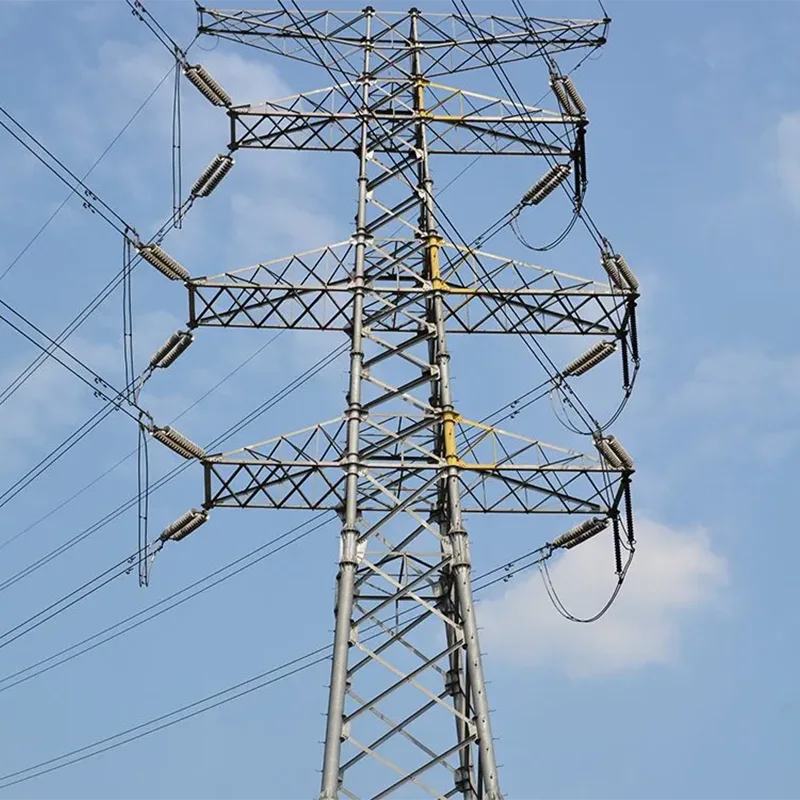

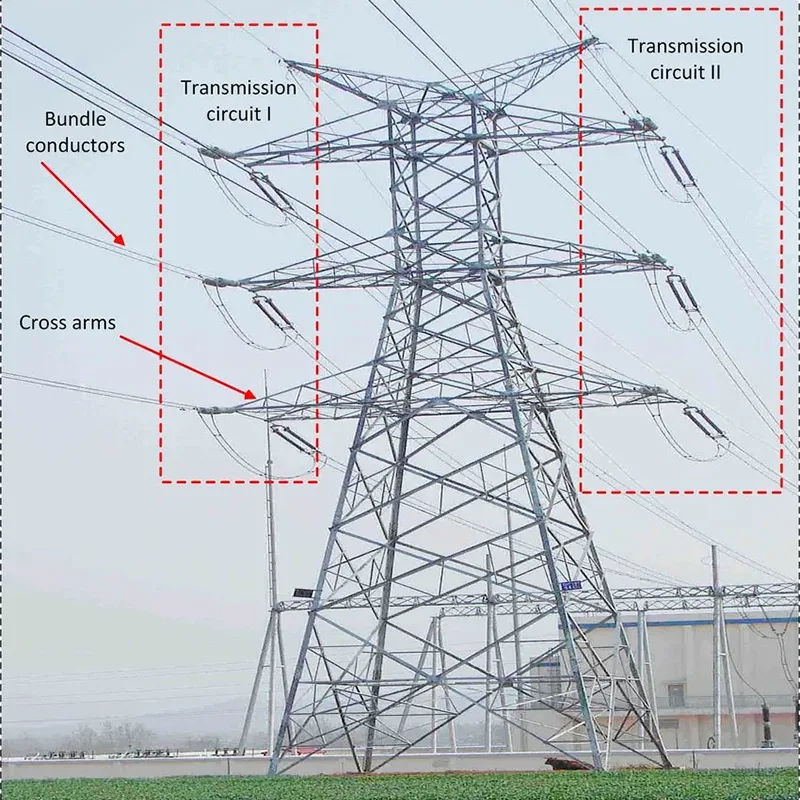

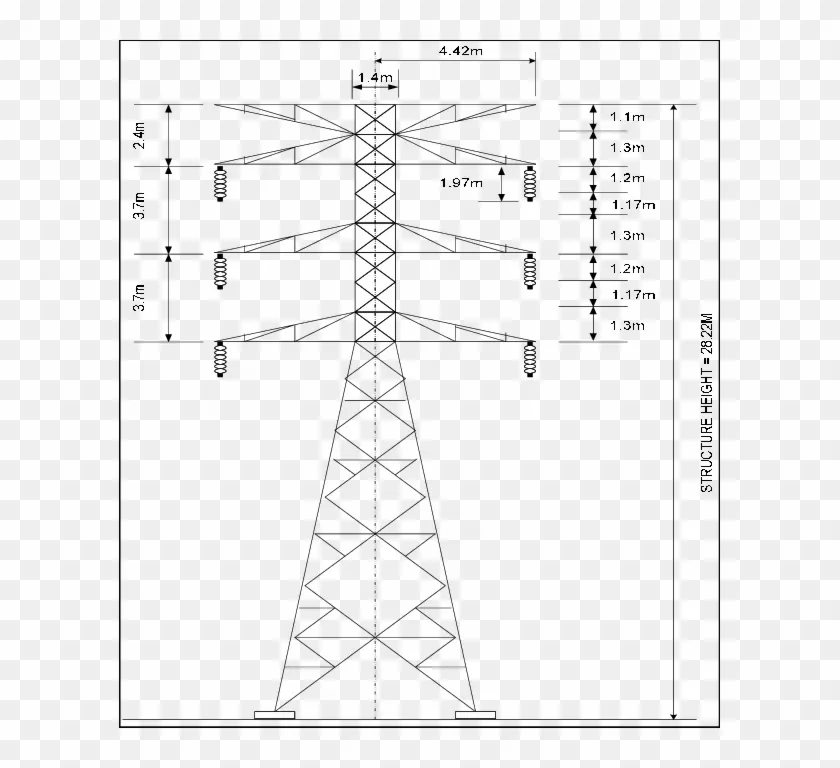

132kV Double Circuit Transmission Tower

Maotong's high-quality 132kV Double Circuit Transmission Tower is designed to meet the high transmission capacity requirements of modern grid extension. Compared with a single-loop tower, the structure can simultaneously carry two independent loops, and the transmission capacity is doubled without increasing the floor space.

Send Inquiry

As the professional manufacturer, Qingdao Maotong Power Equipment would like to provide you high quality Qingdao Maotong Power Equipment 132kV Double Circuit Transmission Tower, which adopts high strength structural steel (Q355/Q420) and combines precision CNC machining technology to ensure convenient and efficient field assembly.

Key Features & Benefits

Optimized spatial layout: Vertical arrangement of conductors, significantly reducing the footprint of tower base, suitable for suburbs, mountainous areas and narrow transmission corridors and other terrain conditions.

Good corrosion resistance: All steel parts are hot dip galvanized according to ISO 1461 or ASTM A123 standards. With an average zinc coating thickness of more than 85μm, our 132kV Double Circuit Power Transmission Line Lattice Towers are guaranteed a service life of more than 50 years, even in high humidity environments.

Precision manufacturing: We use advanced CNC angle lines for cutting and stamping. This ensures hole-to-hole accuracy within ± 0.5 mm, eliminates the need for field redrilling, and shortens the project Timeline by 20%.

High Load adaptability: According to PLS-CADD design simulation, the lattice structure is designed to withstand strong wind loads (up to 160 km/h) and icing.

Get A Quote Now

Product parameters

|

Parameter |

Specification |

|

Product Name |

132kV Double Circuit Transmission Lattice Tower |

|

Voltage Level |

66kV / 110kV / 132kV / 138kV |

|

Tower Type |

Suspension / Tension / Terminal / Angle Tower |

|

Structure Material |

High Strength Low Alloy Steel (Q345B/Q420/ASTM A572 Gr50) |

|

Surface Treatment |

Hot Dip Galvanization (Zinc Coating > 600g/m²) |

|

Wind Speed Design |

100 km/h - 180 km/h (Customizable) |

|

Design Standard |

GB/T 2694, IEC 60826, ASCE 10, ASTM |

|

Certificates |

ISO 9001, ISO 14001,ISO 45001,OHSAS 18001 etc. |

|

Spare Parts |

Foundation Bolts, Nuts & Washers, Anti-theft Devices |

Get A Quote Now

Manufacturing & Quality Control

At Qingdao Maotong, quality is our top priority. Our production process strictly follows the following points:

Material Inspection: All steel raw materials have factory certificates and chemical analysis before warehousing.

Trial Assembly: Before extensive galvanization, we conduct trial assembly (preassembly) on the ground to verify the assembly of each connecting plate and bolt. This ensures a 100% pass rate at delivery.

Final Pack: The tower materials are bundled and distinguished by color codes for quick identification and classification at the installation site.

Get a Quote for Your Project

Need a customized design or pricing for 132kV towers? Send us your technical drawings or project requirements (Voltage, Wind Speed, Span). Our engineering team will provide a detailed proposal within 24 hours.

Get A Quote Now