- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Angle Steel Tower

- Electric Transmission Angle Steel Tower

- Communication Angle Steel Tower

- Monitoring Angle Steel Tower

- 220kv Transmission Line Electric Angle Steel Tower

- 110kv Transmission Line Electric Angle Steel Tower

- 330kv Transmission Line Electric Angle Steel Tower

- 500kv Transmisson Line Angle Steel Tower

- 66kv Angle Steel Tower

- 66KV Angle Steel Electric Power Tower

- Communication Towr

- Steel Pipe Tower

- Transmission Line Steel Pipe Tower

- Single Steel Pipe Tower

- Telecommunication Steel Pipe Tower

- Monopole Steel Pipe Tower

- 3 Leg Steel Tube Pipe Tower

- 220KV Steel Pipe Tower

- 110KV Steel Pipe Tower

- Lightning Steel Pipe Tower

- 500KV Steel Pipe Tower

- 66KV Steel Pipe Tower

- 330 KV Steel Pipe Tower

- Telecommunication Single Tubular Tower

- 10KV Steel Pipe Tower

- 10KV SIngle Pipe Tower

- 800KV Steel Pipe Tower

- Single Pipe Tower

- 132KV Steel Pipe Electric Power Tower

- 10KV-220KV Steel Pipe Electric Power Tower

- 4 Leg Telecommunication Microwave Tower

- High Voltage Communication Tower

- High Voltage Tesnsion Power Tower

- Single Tubular Monopole Tower

- Substation Steel Structure

- Angle Bar Tower

- 750KV Angle Steel Transmission Line Tower

- 10KV 33KV Transmission Line Tower

- 330KV Angle Steel Transmission Line Tower

- Tesioning Electric Transmission Tower

- 1000KV Electric Angle Steel Tower

- Lightning Tower

- Training Tower

- WiFi Communication Tower

- Power Line Tower

- Tangent Suspension Tower

- Terminal Tower

- Tension Steel Tower

- Single Monopole Tower

- Suspension Angle Steel Line Tower

- Angular Steel Electric Tower

- High Voltage Tower

- 66kv 120kv 220kv Steel Tower

- Transmission Electric Line Steel Lattice Tower

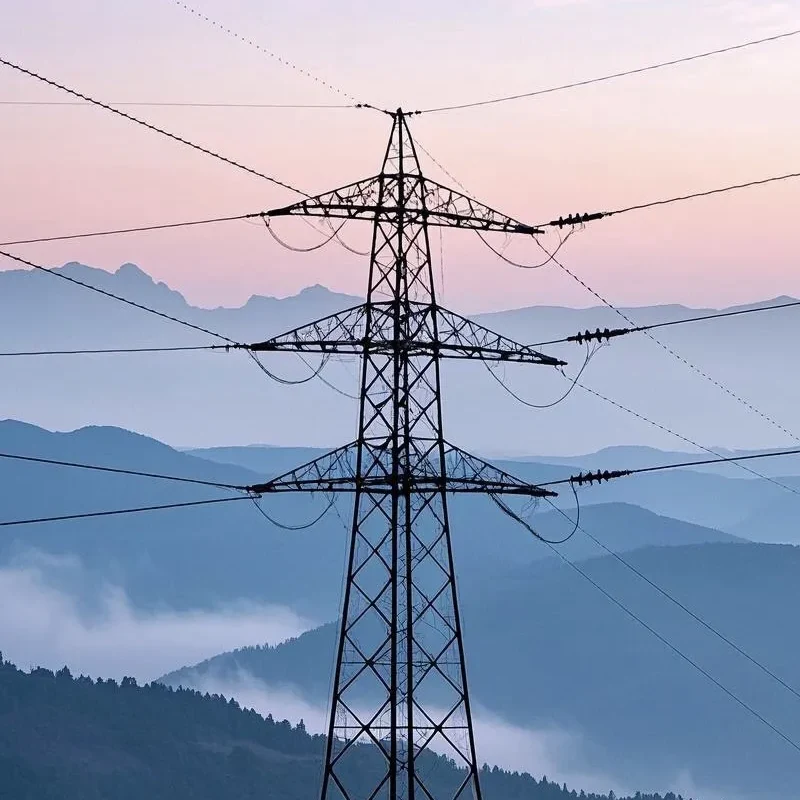

Metal Electric Power Tower

Metal electric power tower is an important structure used in power systems to support and transmit power lines. Maotong has many years of experience in producing Metal electric power towers. Metal electric power towers are used in various power systems to support high-voltage or ultra-high-voltage transmission lines to ensure the safety and stability of power transmission.

Send Inquiry

Metal electric power tower is mainly made of metal materials such as steel, and has the characteristics of high strength, good stability and corrosion resistance. Metal electric power tower is widely used in various power systems, such as urban power grid, rural power grid, power plant, substation, etc. They support high-voltage or ultra-high-voltage transmission lines to ensure that electricity can be safely and stably transmitted to every corner. As an important power facility, Metal electric power tower has the advantages of high strength, corrosion resistance, easy construction and beautiful appearance, and plays a vital role in the power system.

Get A Quote Now

Specification

|

Product Name |

Metal electric power tower |

|

Material |

Iron |

|

Country of origin |

Shandong China |

|

Suitable |

Power transmission and distribution |

|

Shape |

Polygonal or conical |

|

Power capacity |

10kV to 500kV |

|

Size |

Custom |

|

Brand |

Maotong |

Product Features

1: Space truss structure: Metal electric power tower usually adopts space truss structure, which is composed of multiple rods connected by nodes to form an overall stable structural system.

2: Rod material: Metal electric power tower rods are mainly composed of single equilateral angle steel or combined angle steel, and the material generally uses high-strength steel such as Q235 (A3F) and Q345 (16Mn).

3: Connection method: Metal electric power tower rods are usually connected by bolts, and the overall stability of the structure is maintained by shearing the bolts. Some parts such as tower feet may be connected by welding.

4: Anti-corrosion treatment: In order to extend the service life, Metal electric power tower usually needs to be treated with anti-corrosion, such as hot-dip galvanizing, to improve its corrosion resistance.

Get A Quote Now

Scene pictures

FAQ:

1. How is the price calculated?

Ex-factory, FOB, C&F or CIF.

For FOB, CFR or CIF prices, please indicate the exact model you require and tell us your order quantity so that we can calculate the local freight and ocean freight.

2. What is the company's minimum order quantity?

Customized 1 set

3. How long is the payment term?

Generally, 30% deposit is paid by T/T, and the balance is paid by T/T or L/C at sight before shipment. Other payment methods can be negotiated.

4. What is your company's delivery time?

For 30 sets, ready to ship within 20 working days after receiving the deposit

5. How can I get the price of the required rod?

Please give the specific dimensions, such as tensile strength, height. thickness, material, top and bottom diameter. We can give you a similar price based on your specifications. You can also give us a drawing and we can give you a price based on your drawing.

6. How about the packaging?

Plastic paper or as per request

7. How long is the component design service period?

Twenty years, guaranteed service.